|

What is the difference between cooling the outdoor cabinet by fan (ventilating unit) versus CoolSpot (air-conditioning unit with compressor)?

- Fans bring fresh air into the cabinet – but also a lot of dust and humidity. The AC unit circulates indoor air without these disadvantages.

- If a fan is used, the air inside the cabinet never can be colder than the air outdoors . The temperature indoors increases because of the internal heat load and external sunshine ( a very large heat load!!). Heat rejection is a result of changes in air. If the AC is used, the temperature in the cabinet can be much lower than the ambient temperature.

- AC power consumption is much larger than fan consumption because of the compressor.

- CoolSpot AC units do not have any controls except on/off, which causes the internal temperature to fluctuate very much. The amount of fluctuation depends on the difference between the cooling capacity and current heat load. Correct design of the AC is very important, and the correct estimation of heat load is fundamental. Temperature fluctuation can be limited by higher heat accumulation in the cabinet, which means a higher weight of the cabinet or components.

If the display on AC-SO-XX is ”frozen,” and is impossible to control

- We recommend that you restart the AC unit in order to fix the problem. Eventually you can replace the display.

If the compressor in the unit CoolSpot AC-TM or WM will not boot up when restarting

- It’s necessary to check whether door contact is being made

If the fan in the CoolSpot AC-TM or WM unit is not working

- The reason is probably a damaged starting capacitor.

Dual Fluid cooling units

Advantages:

- There are two heat exchangers in each unit.

- All units can be connected to two different cooling systems (e.g. chilled water for summer, and DX for winter operation)

- Theoretically, in case of cooling system failure , the second alternate system can be used. Only the N unit is needed (instead of N+1) in the room.

But the real situation – the probability of total cooling system (e.g. water system with chiller) collapse, is very low in comparison with the probability of a local failure; if one cooling unit breaks down (controller, fan, sensors...), a dual heat exchanger cannot help. N+1 units are needed as a result, if this should occur.

Disadvantages:

- Full cooling capacity must be ensured by one of either heat exchangers, as we cannot expect that both will be working together.

- Using two large heat exchangers can cause a sudden drop in air pressure (obstacles in the airflow), which drastically increases the consumption of power in the fan.

- If any part of the unit is imbalanced, the whole unit must be repaired. If dismounting is necessary, then both cooling systems are disturbed.

We recommend using a combination of different units in order to ensure the redundancy in the room, or using single fluid units connected to the two water systems.

If experiencing leakage from the CoolSpot unit

- Discharge of condensate is not “water leakage”. The unit must be always connected to a drainage system (or vessel). Condensation consists of humidity (water vapor or steam) from the air converted to liquid water on the cold surface based on physical laws.

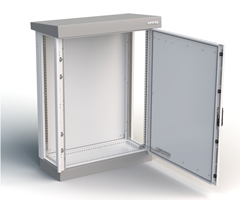

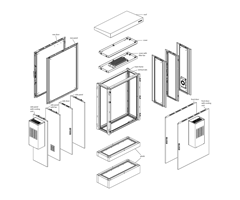

CoolSpot can be used only on side panel?

There are two reasons for not using it directly on the door:

- Due to its weight, (we use a special reinforcing frame on the side panel to make the unit firm), which can’t be used with a door because of blockage.

- The idea that the unit will blow cold air into the rear side of the servers is nonsense.

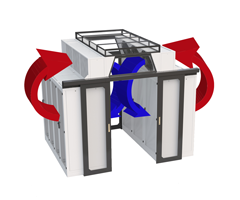

Typical rear door cooling units are based on another principle: hot air is collected from the rear side of the cabinet, and the cold air is blown into the room. Our unit blows cold air into the cabinet. For more

information, please review the pictures

in our Conteg catalogue.

What is the requested humidity in the data center?

- The requested humidity isn’t dependent on geographic situation, but on both the interior hardware and severity of the DC. Sometimes 45-55% is demanded (very strict), sometimes 40-60% is possible, while the mildest (very meek) demand is 35-70%. This is the reason why these limits are preselected in the software. But the user can employ stricter conditions within these limits. We do not recommend using a humidity lower than 35%, because of the risk of electrostatic effects in the room. Humidity levels exceeding 70% can cause condensation and hardware corrosion.

- The geographic situation affects the demand of humidification (or dehumidification) during operation. If your project is close to the sea, you can expect a moist environment, and perhaps do not need a humidifier within the unit; expect frequent use of the dehumidification mode (which is controlled automatically by the unit), however.

- We recommend setting the humidity to a value of 40-60%. If the dehumidification mode starts up too often ( indicated by a “droplet symbol” on the screen), you can increase it to 40-70% (in order to save the energy, because the dehumidification mode consumes more energy).

What is the limit for temperature setpoint in CoolSpot units?

- The limits for temperature setpoint are between 25°C and 45°C. You can set the minimal setpoint at +25°C, which means the hottest incoming air ( to the AC unit) has a temperature of +25°C. Outgoing air is about 15°C; it must not be much lower because of the risk of condensation.

- Temperature is measured in the suction area of the AC unit. If either the setpoint temperature is reached or the temperature is lower, the compressor is off. If the cabinet temperature (intake of air to AC unit) is higher than the setpoint + hysteresis (parameter “rd = Differential”), then the compressor is on.

- The following is an example of the WallMount CoolSpot unit (AC-WM) in operation: If you set the temperature at +25°C, the actual temperature in the cabinet will be between 15 and 25°C, depending on the position . When cold air (ca +15°C) is blowing into the lower part of the cabinet, the air cools the IT components inside and becomes warmer. Hot air (25°C) returns to the AC unit. This is the correct function of the CoolSpot unit.

- In the case of a TopMount CoolSpot (AC-TM) unit being employed, the cold zone in the front part of the IT rack should be full of the “cold” air (approx. 15-20°C), discharged from the AC unit. The hot zone in the rear part of cabinet will be full of hot air (max.25°C), which is sucked into the AC unit.

Ammonia

- Absorption cooling with an ammonia circuit is a more common kind of cooling mechanism, compared with using a compressor , though not often used within buildings (it is more typical for ice-hockey stadiums, etc.). In the last few years, however, it has become very modern, because waste heat can be used as a driving energy for this system.

- For example, a solar power plant can produce electricity (as a primary result) and heat (as a secondary, ballast product), which can be used for cooling –perfect for producing cold directly from heat.

- But there are two basic problems: ammonia is toxic (and very smelly), and the price of such machinery is very expensive, so not a very good return on investment at the moment. In a couple of years, however, it could also become a proper system for data centers.

Is it possible to use DX units for heat recovery?

- Our standard DX units employ an outdoor compressor unit, in which heat is transferred to the air outside, without any possibility of reuse. If a chiller is used ( e.g as in our Test lab ) heat from data center is transferred to the water, which (at a temperature of about 45°C) can be cooled down either by outside air (without heat reuse), or used as a heating medium in the building. For this reason, the CW system with special chiller (for heat recovery) is required.

Is it possible to use tap-water for cooling the data center?

- Tap water can be used for cooling – but you can imagine the price of the drinking water (about 4000 liters per hour, or 35 040 000 liters per year). We often use it as a redundant solution in failure situations—not for standard operation; also, the waste heat cannot be reused, because the temperature of the incoming water is about 10°C ( supplied using tap-water ), while the outgoing temperature is about 15°C, and so not possible for heating use.

Does the condensation pump work independently of the unit?

- Yes, it does— with the CoolTeg unit. A water-level sensor in the condensate pan is standard equipment in each CooTeg Plus unit – complete with an alarm signal to CoolTeg controller. In case of high water levels, the unit sends an alarm and shuts down. This is a significant error of the function, risky in the DC room. Stopping the unit can save the room from water, in this case.

Is it necessary to install a humidifier in each unit?

- You can integrate the humidifier into each unit, though customers typically want to save their money, so buy only one humidifier for smaller rooms. In case of humidifier failure, it isn’t critical technology for the IT equipment .

Is it necessary to use a condensation pump in each unit?

- If there is no possibility of gravity drainage, a condensation pump has to be installed in each unit.

What is TIER?

- TIER certification is a means of identifying different data centers. It is a world standard, which divides data centers into four categories, as specified by the Uptime institute. TIER classifies and compares the characteristics and availability of data centers.

What is dew-point temperature?

- This means the air is fully saturated. In case of lower temperatures, the water vapor contained in the air begins to condense. Water vapor condenses on surfaces with lower or equal temperatures than the dew-point temperature, therefore it’s important to monitor this value.

Which situations are better for using the DX or CW system?

DX

- Easy installation for smaller applications

- Ideal for total capacities up to 100 kW

- Refrigerant piping up to 75m

CW

- Ideal for applications of 4 coolers (80 kW) or higher

- For non-limited cooling capacities and distances

- Wide range water temperature setting

- Possible connection to free-cooling chillers

- Compressor circuit in separate chiller

What is ASHRAE?

- ASHRAE stands for the American Society of Heating, Refrigerating, and Air-Conditioning Engineers. Founded in 1894, the Society and its more than 50,000 members worldwide focus on building systems, energy efficiency, indoor air quality, refrigeration and sustainability. Through research, standard-writing, publication, certification and continuing education, ASHRAE shapes tomorrow’s built environment today.

Do units always have a catalogue cooling capacity?

- Certainly not. Unit cooling capacity is based on many parameters—namely the difference in temperature between both air and heat exchanger surfaces ( which depends on the inlet water temperature and water flow), airflow, and humidity. In general, the higher the temperature difference, the better the heat exchange. By increasing the airflow, the total capacity increases because of a higher quantity of heat medium.

What is the typical heat load of a single rack?

Communication 80 kW/m2

Storage center 20 kW/m2

Workstation 8 kW/m2

Tape Storage 2 kW/m2

What is PUE?

- PUE stands for Power Usage Effectiveness, the most often assessed value for energy effectiveness rating in data centers. It is a ratio of consumed energy for both IT equipment and support system energy.

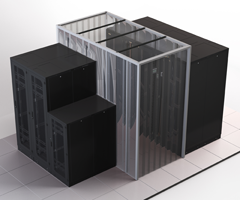

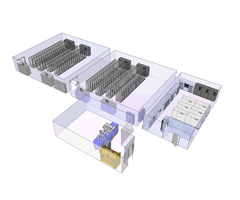

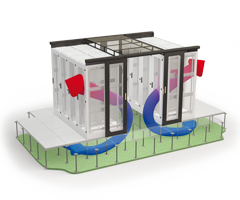

Which room arrangement is the best?

Each application has its own specifics. Each project must be solved individually. Every project should meet the following parameters:

- Maximally ensure separate hot and cold zones.

- Most effective delivery of cold air to the racks

- Minimum power consumption of the system as a whole

- Minimum fan power consumption

- Minimum maintenance

Factory setting valves of CW30 and CW60 units

CW30_Factory setting of the 3-way valve.

Electricity backup

- The critical infrastructure of a data center requires continuous performance. ICT heat is dissipated from the data centers through the AC units and into an environment. If power is cut, the ICT is backed by the UPS for the time necessary to start the motor generator –usually one minute. If the AC unit was not backed by motor generator, the heat would not be able to dissipate into the environment. There is a risk of overheating, and even damage to the ICT, due to the high temperatures. This increase in temperature of the critical value occurs within a few tens of seconds to minutes. If the AC system is not powered by the UPS, air temperature in the cold zone may slightly increase during the blackout, before the motor generator is ready; this usually takes only a minute, and does not affect continuous performance of the ITC equipment. For this reason, it’s necessary to connect the AC system to a backup motor generator not powered by the UPS.

What’s the difference between AC & EC fans?

Advantages of EC fans:

- Ability to operate at low speed

- Significantly lower power consumption

- Fluent regulation of airflow

- Long lifetime

- Low operating noise

- Up to 30% savings, compared to AC fans

- Control and protection functions integrated into a control unit inside the motor

Main advantages of Pressure Control

- Extends server lifetime

- Reduces fan power consumption

- Eliminates hotspots and dustiness in front of servers

- Can be installed directly into the CoolTeg Plus, or in a separate box

Are all the units going to work in a group with only one display, or will each be independent, with its own display?

- There are a maximum of two units per display, which can communicate with each other. If each unit has its own display, they cannot work in one group. Only two displays are permitted in one group. If the units are not grouped, they cannot be controlled by pressure. Other features aren’t a problem, with the CW system. It is very unfriendly for the user to have a display on each unit, because he has to set the values a total of six times. Nor can he download the history values easily, because he cannot see all of them in one place, etc. Perhaps the most important point is that it’s a waste of money to have six displays, when two will do. This is the great advantage of our system, which enables customers to control all their units from one location.

What is the fan storage temperature?

- The storage and transport temperature of DP-VEC-xx fans is -40°C to +80°C.

- The operating temperature is in the range -20°C to 70°C.

Is it possible to connect the CoolTeg DX unit to an outdoor unit with a higher capacity?

- Our AC-TDX-xx-.... is fully compatible with PUHZ-xx125, 200 and 250. We use 250 for longer distances between indoor and outdoor, in order to keep the performance level at about 20kW, because the cooling capacity decreases with distance. The maximum for total cooling capacity is 20kW, even though the outdoor unit capacity is higher. The AC-TDS-xx-... (DXSmall) is compatible only with PUHZ-xx71.

|