-

Products IT

ProductsConteg products are based on the needs of customers around the world and the latest developments in the field.

-

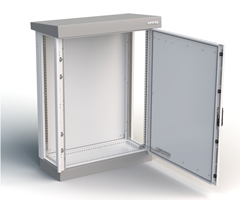

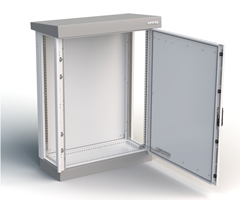

Free-Standing Racks

Free-Standing RacksFree-standing racks are used for the secure installation of both active and passive equipment, including required power and telecommunications cabling.

- PREMIUM Server RSF

PREMIUM Server RSFThe best in class server 19" cabinet designed for data centers, equipment rooms and network or telecommunication closets.

- PREMIUM RSF BYTEline

PREMIUM RSF BytelineAfter thorough research, we have prepared a list of the most requested rack configurations for data center projects called PREMIUM Server RSF-BYTEline

- PREMIUM Cabling RDF

PREMIUM Cabling RDFA top-quality cabling cabinet designed for data centers, equipment rooms and network or telecommunication closets.

- PREMIUM Housing RSB

PREMIUM Housing RSBDesigned to operate in server housing and co-location centers where they can be installed as stand-alones or arranged in rows.

- iSEVEN RI7

iSEVEN RI7Designed to provide the user with an unmatched combination of price, utility and quality.

- iSEVEN SERVER

iSEVEN SERVERThis rack configuration fulfills most demand and brings an unattainable price / performance ratio making it ideal for day-to-day use of the product.

- iSEVEN Flex RM7

iSEVEN Flex RM7Designed for users whose space constraints do not allow for the installation of rack series iSEVEN (Ri7) with welded construction.

- iSEVEN Flex SERVER

iSEVEN Flex SERVERThis rack configuration fulfills most demand and brings an unattainable price / performance ratio making it ideal for day-to-day use.

- Special OPTIMAL

Special OPTIMALRacks from the Special OPTIMAL line are best suited for specific use areas. They can be installed as stand-alone or arranged in rows for server rooms and data centers.

- Space Optimisation Sections

Space Optimisation SectionsSpace Optimization Sections are designed to give additional layout flexibility to data centers.

- PREMIUM Server RSF

-

Open Frames

Open FramesOpen frames are used wherever it is not possible or not desirable to use racks or when unrestricted access to the installed equipment is necessary.

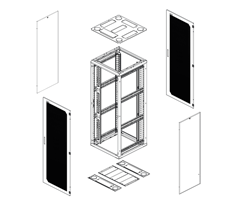

- Open Frames RSG4

Open Frames RSG4The double high-load open frame RSG4 series is designed for high-density installations of any equipment in closed rooms.

- Open Frames RSG2

Open Frames RSG2RSG2 high-load, two-post open frames are designed for high-density cabling applications that are used in combination with High Density Wire Managers.

- Open Frames RS Series

Open Frames RS SeriesThe RS frame series is designed for IT components in closed rooms with controlled access and environments suitable for operating installed components.

-

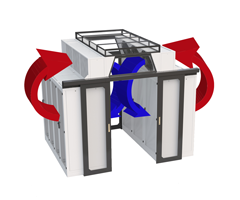

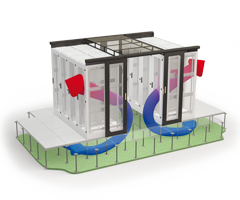

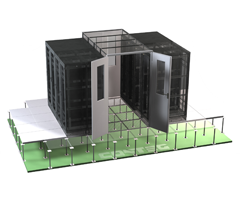

Contained Aisle Solutions

Contained Aisle SolutionsThe contained aisle solution is the most effective way how to maximize cooling capacity and minimize operational costs.

- Cooling above racks

Cooling above racksCoolTop units don’t occupy any floor space so the Data center can use this free area for IT equipment, resulting in higher profitability.

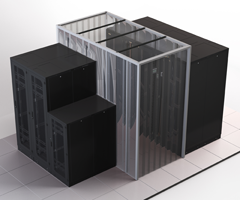

- Contained Aisle - Fixed Solution

Contained Aisle - Fixed SolutionFixed Contained Aisle solution is the ideal way to contain rows of racks of same height and width.

- Contained Aisle - Modular Solution

Contained Aisle - Modular SolutionThese solutions are the ideal way to contain rows of racks of different sizes or when there are gaps between racks.

- Modular Closed Loop

Modular Closed LoopModular Closed Loop solution for high-density areas to separate cold and hot air that offers energy-savings, IT equipment protection, and optimal space utilization.

-

Wall-Mounting & SOHO Racks

Wall-Mounting & SOHO RacksThe portfolio for wall-mounted racks and racks for small offices or households (SOHO) contains 7 rack series of all types and designs.

- Wall-Mount PREMIUM RUN

Wall-Mount PREMIUM RUNThe Wall-Mount PREMIUM RUN offers an extended level of access to installed equipment through the front door.

- Wall-Mount PREMIUM Split RUD

Wall-Mount PREMIUM Split RUDThe Wall-Mount PREMIUM Split RUD offers the highest level of access to installed equipment: through the front door.

- Wall-Mount iSEVEN REN

Wall-Mount iSEVEN RENThis economy version of a wall-mounting rack offers a sufficient level of access to the installed equipment through the front door.

- SOHO Mini REH

SOHO Mini REHThe SOHO racks in the REH series are ideal for installations of 10" patch panels, shelves, SOHO active elements, etc.

- SOHO In-Wall

SOHO In-WallThe SOHO racks in the ACP series are designed for households and in small offices and are „concealed“ in the wall.

- SOHO On-Wall

SOHO On-WallThe SOHO On-Wall 19" distribution enclosure is aesthetically pleasing and offers greater flexibility during the installation process.

-

Targeted Cooling & Ventilation

Targeted Cooling & VentilationThis chapter presents products used for air-flow regulation and optimization; their use is recommended for efficient cooling.

- CoolSpot

CoolSpotCoolSpot cooling units are designed to remove low and medium heat loads in individual racks.

- CoolTeg Plus

CoolTeg PlusCoolTeg Cooling units are designed to cool very high-density heat loads, which occur in modern data centers and server rooms.

- CoolTop

CoolTopCoolTop represents a family of precision cooling units specifically designed for installation on top of IT racks in server rooms and large data centers.

- Chillers

ChillersThese devices produce cold water and supply it to the indoor cooling units, sending heat from the datacenter into the ambient environment.

- Ventilation

VentilationVentilation units and fans are used for cooling equipment installed in the rack.

- Airflow Management

Airflow ManagementPassive elements of airflow control are used to regulate the airflow inside the cabinet and create separate zones. Their application is for efficient cooling of equipment.

- S-T-S Airflow Support

S-T-S Airflow SupportSide-to-Side Airflow Support solution allows you to use high-speed network components near servers.

-

Cable Management

Cable ManagementAre you looking for a cable management system? You can choose from our cable brackets and duct for Conteg racks.

- High Density Wire Management

High Density Wire ManagementThe new range of High Density Wire Managers from Conteg ensures cabling is properly managed.

- OptiWay

OptiWayOptiWay is a safe, easy-to-use and cost-effective management system for your fragile optical cables.

- Standard Cable Management

Standard Cable ManagementStandard management products are used for vertical or horizontal routing cables in the rack.

- Top Ducts

Top DuctsTop Ducts are designed to provide safe, easy-to-use, and cost-effective management system for copper cables above the racks.

-

Power Distribution Units

Power Distribution UnitsConteg`s power management products seek to address the growing demand for power distribution within stand-alone racks, server rooms and data centers.

- Intelligent Power Managed

Intelligent Power ManagedManaged Power Strips combine the industry's leading high-density power solutions.

- Intelligent Power Monitored

Intelligent Power MonitoredThe Intelligent Power Monitored strips provide reliable power to the cabinet in both standard and blade-server environments.

- Basic Power Distribution Units

Basic Power Distribution UnitsConteg Basic Power Distribution strips offering configurations that are common in today's high-density computing environment.

-

Complementary Systems

Complementary SystemsOur systems help you monitor the environment inside and outside the cabinet and respond to any critical situationin a timely manner.

- Aegis DCIM

Aegis DCIMConteg's Aegis Data Center Infrastructure Management system collects, analyzes, reports and manages infrastructure equipment.

- CONTEG Pro Server Management Software

CONTEG Pro Server Management SoftwareCONTEG Pro Server takes the best from environmental and security monitoring and access control systems and puts it into one centralized management software package.

- Rack Monitoring Systems - RAMOS

Rack Monitoring Systems - RAMOSThe RAMOS family of rack monitoring products includes four different versions, each tailored for a different monitoring application.

- Access Control Systems

Access Control SystemsThe Access Control System makes using CONTEG racks even easier and housing all equipment even safer

- KVM/LCD Solutions

KVM/LCD SolutionsThe KVM/LCD solutions offer a spatially efficient design (integration in 1U) and allow configuration and management of individual servers and their cascades.

- Local Extinguishing Systems

Local Extinguishing SystemsThe LES-RACK is a self-contained, fully automatic detection and fire protection system.

-

Accessories

AccessoriesProducts for shelving, optic racks, plinths, mounting kits and many other necessary accessories.

- Shelving

ShelvingFixed and telescopic shelves are featured in the Conteg portfolio to support equipment that cannot be rack mounted.

- Fiber-Optic Products

Fiber-Optic ProductsAre you looking for fiber-optic products? Our portfolio offers many options, including fiber-optic splice boxes.

- Rack Casing

Rack CasingEach rack line offers a wide range of doors, side panels and top and bottom plates. We also offer many door locks systems.

- Patch Panels

Patch PanelsPatch panels are installed on the 19" vertical extrusions and used for cable termination.

- Earthing

EarthingConteg racks include a standard earthing kit.

- Modular Plinths

Modular PlinthsPlinths are aesthetic and stabilizing features for free-standing racks.

- Castors and Feet

Castors and FeetConteg free-standing racks have a standard configuration with height-adjustable feet. The feet can be replaced by castors or plinths.

- Mounting and Connecting Kits

Mounting and connecting kitsAre you looking for a connecting kit to connect (bay) your racks together? You can also find mounting kits in this section.

- Others

OthersOur accessories also include cable protection, wall-mounted holders and lighting units.

- 10" SOHO Accessories

10" SOHO AccessoriesThe RSH SOHO racks are the only Conteg racks with 10" vertical extrusion spacing.

- Shelving

-

Outdoor Cabinets

Outdoor CabinetsOutdoor cabinets securely protect electrical equipment against weather conditions.

- outTEG II Double Natural

outTEG II Double NaturalOutdoor double-walled cabinet with natural ventilation/convection-cooling.

- outTEG Customized Solutions

outTEG Customized SolutionsWe will prepare a customized solution which meets your specific requirements.

- Outdoor Climate Control

Outdoor Climate ControlFilter fans, cooling units or heaters maintain a proper operating climate for equipment installed inside the cabinet.

- Interior Installation

Interior InstallationMounting plates, Rails, Side panels, Doors, Baying kits, Fixing frames

- Accessories

Accessories outTEGWe offer wide range of accessories for outdoor cabinets

- 19" accessories

19" accessoriesWe offer wide range of accessories for outdoor cabinets for 19"

-

Free-Standing Racks

-

Products Industry

IndustryWe offer complex solutions for applications in industrial, electrical engineering and automation field - enclosures for indoor and outdoor use, including complete climate control solutions.

-

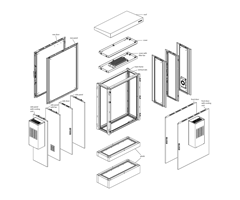

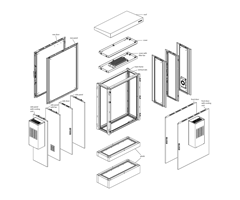

inTEG Compact Enclosures

inTEG Compact EnclosuresOur compact inTEG enclosures have a smooth design thanks to the latest laser-welding technology.

- Enclosures – sheet steel

Compact Enclosure – sheet steelSheet-steel enclosure with powder-coating in RAL 7035 is the standard. We offer single-door and double-door enclosures.

- Enclosures – glazed door

Compact Enclosure – glazed doorAll dimensions of sheet-steel enclosures are also produced with glazed door.

- Enclosures – stainless steel

Compact Enclosure – stainless steelThe stainless-steel compact enlosures are suitable for application that need more protection from the environment.

- Enclosures – outdoor

Compact Enclosure – outdoorIdeal solution for outdoor applications is stainless-steel enclosure with outdoor powder-coating and rain canopy.

- Compact Enclosure Accessories

Compact Enclosure AccessoriesWe offer wide range of accessories for all produced inTEG compact enclosures.

- Safety warning signs

Safety warning signsChoose safety warning signs from our standard portfolio or we can produce it according to specific requirements.

- Enclosures – sheet steel

-

inTEG Free-Standing Enclosures

inTEG Free-Standing EnclosuresThe welded enclosure frame is made of special galvanized steel profile that has been cold rolled.

- Enclosures – Sheet Steel

Enclosures – Sheet SteelinTEG Industrial Free-standing enclosures - sheet steel with single or double door

- Accessories

AccessoriesAccessories for inTEG Free-Standing Enclosures

- Safety warning signs

Safety warning signsChoose safety warning signs from our standard portfolio or we can produce it according to specific requirements.

-

Outdoor Cabinets

Outdoor CabinetsOutdoor cabinets securely protect electrical equipment against weather conditions.

- outTEG II Double Natural

outTEG II Double NaturalOutdoor double-walled cabinet with natural ventilation/convection-cooling.

- outTEG Customized Solution

outTEG Customized SolutionIf you require a customized solution with climate control system or have any installation or application questions, please contact us.

- Outdoor Climate Control

Outdoor Climate ControlFilter fans, cooling units or air/air heat exchangers maintain a proper operating climate for equipment installed inside the cabinet.

- Interior Installation

Interior InstallationMounting plates, Rails, Side panels, Doors, Baying kits, Fixing frames

- Accessories outTEG

Accessories outTEGWe offer wide range of accessories for outdoor cabinets.

- 19" accessories

19" accessoriesWe offer wide range of accessories for outdoor cabinets for 19"

-

Climate Control Solutions

Climate Control SolutionsCooling units maintain a stable thermal comfort for the installed components inside the enclosure.

- Filter Fan Units

Filter Fan UnitsForced ventilation fans maintain the correct temperature inside the cabinet by exchanging heated inside air for cool outside air.

- Cooling Units

Cooling UnitsOur cooling units are designed to operate with an absolute minimum need of maintenance.

- Thermoelectric Cooler

Thermoelectric CoolerThermoelectric cooling uses the Peltier effect to create a heat flux between the junctions of two different types of materials.

-

inTEG Compact Enclosures

-

Solutions

SolutionCONTEG's range of high quality racks, frames and cable management products help to ensure a stable operating environment in your data center.

-

Data Centers

Data CentersA data centre can be defined as a facility used to house computer systems and associated components, such as telecommunications and storage systems.

- Design Support

Design supportOur company offers the services of experienced professionals from all technical areas required for the construction of a modern data center.

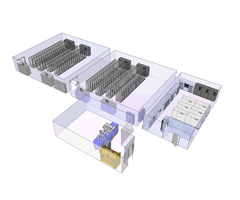

- Total Solutions for Data Centers

Total Solutions for DCThe proper layout and design of a data center will ensure reliable safe operation, low energy consumption and high availability of installed ICT system.

- Design Support

-

Enterprise Solutions

Enterprise SolutionsNo matter what size your company is, ensuring reliable communication and ICT is crucial to conducting business activities successfully.

-

Server Rooms

Server RoomsHere we have selected products suitable for a modern server room including racks, open frames, central network switches, optical and metallic cables.

-

TELCO

TELCOPhone, e-mails, data sharing on social networks? Everyday technology we cannot be without.

-

Networking

NetworkingLooking for a way how for the best way to house cabling and IT equipment? We have networking racks that provide a correct fit for these.

-

Home & Office

Home & OfficeAt home and in the office you can have IT and telecommunications technology positioned safely and clearly.

-

Outdoor network

Outdoor networkOutdoor cabinets securely protect electrical equipment against weather conditions.

-

Industry Solutions

Industry SolutionsinTEG, our industrial enclosures, can be leveraged for industrial solutions.

-

Data Centers

-

Services

ServicesConteg provides its customers with services for all stages of datacenter construction, server rooms and telecommunication rooms.

-

Download

DownloadCatalogs, Brochures, Datasheets, Manuals

-

FAQ

FAQFrequently Asked Questions

- FAQ Cooling Units

FAQ Cooling Units

-

Datacenter Design Support

Datacenter Design SupportOur company offers the services of experienced professionals required for the construction of a DC.

-

Sales Support

Sales SupportIndividual elements of the sales support leading to a successful fulfilment of the customer's expectations.

-

Conteg Product Commissioning

Conteg Product CommissioningConteg offers its customers a wide range of services to ensure that all customers receive the best quality support at all levels.

-

Conteg Assembling Assistance

Conteg Assembling AssistanceAs an important part of our service to our expanding customers we have started to offer a new service.

-

Conteg Certification Program

Conteg Certification ProgramThe Conteg Certification Program provides quality training for our business partners and integrators worldwide.

-

Trainings and Webinars

Trainings and WebinarsCalendar of webinars, training.

-

Partners Zone

Partners ZoneInformations for our Partners. Login required.

- Configurators

ConfiguratorsConfigurators

-

Configurators

ConfiguratorsTo make choosing from our IT rack product line and outTEG outdoor enclosures easier, use Conteg's configurator.

- IT Rack Configurator

IT Rack ConfiguratorConfigure your choice from our RSF, RDF, RI7, RM7 enclosure series, then choose a quote, and we will prepare an offer.

- outTEG Configurator

outTEG ConfiguratorWith our on-line configurator you can comfortably select a suitable outdoor cabinet including its accessories.

- Calculation of IT Air-conditioning Unit

Calculation of IT Air-conditioning UnitCalculation of CoolTeg air-conditioning unit parameters

- Calculation of Cooling Unit for Outdoor Cabinets

Calculation of Cooling Unit for Outdoor CabinetsCalculation of Cooling Unit for Outdoor Cabinets

- Data Centers Configurator

Data Centers ConfiguratorInteractive on-line configurator for data rooms, racks and cooling.

-

Download

-

About CONTEG

About ContegConteg is one of the biggest producers of racks and data center solutions in EMEA.

-

Contacts

ContactsAll important contact information about our company.

-

News

NewsroomConteg News, Youtube videos, twitter

-

Company Information

Company InformationWe are one of the biggest European manufacturers of Data and telecommunication racks and solutions.

-

Career Opportunities

Career OpportunitiesAt Conteg we’re always on the look out for highly motivated, skilled and capable staff to complement our existing team and help to ensure our future success.

-

Reference Projects

Reference ProjectsSelected projects of Conteg worldwide.

-

Environmental Policy

Environmental PolicyCONTEG is certified in accordance with international standard ISO 14001:2004. We have introduced the system to minimize the environmental impact of all our activities.

-

Warranty and Certifications

Warranty and CertificationsIn 2002 we certified our Quality management system in compliance with the international standard ISO 9001.

-

Suppliers

SuppliersDo you wish to become a supplier of CONTEG, spol. s r.o.?

-

Contacts

Passive Airflow Management

|

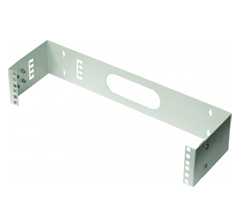

Passive airflow control products are used for optimizing airflow in "front-to-back" airflow applications to minimize bypass airflow. Their application is recommended for efficient cooling of the installed equipment that requires front-to-back airflow. In order to create an efficient cold zone, we recommend the use of a separation frame, blank panels and, in cases of cold air supply from below the rack, a bottom deflector. |

|

Successful air flow management and optimization also requires the application of blank panels into all unused rack Units(RU) to prevent by-pass of cooled air. Double layer brush grommets are also highly recommended for all openings to prevent by-pass air-flow and help maintain static pressure within the raised floor. Application of products mentioned on this page can vary depending on the particular design specifications and equipment or facility requirements. Please do not hesitate to contact us with any questions. We will help you to design the correct solution for the cooling of installed equipment, including efficient air flow management (presales[at]conteg.com).

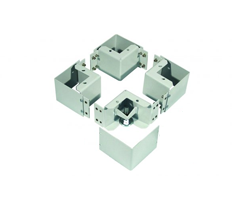

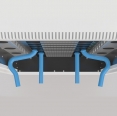

Separation

frame - DP-RSF-CW, DP-ROF-CW, DP-RxF-CW Modified version of Air Separation frame allows a simple installation of the frame inside the rack and consequentially joins two racks together. This version of separation frame is compatible with the new QUICK Connecting Kit ‑DP‑DR‑UNI‑Q. When both products are used together is it possible to use pre‑installed Air Separation frames directly from producer or system integrator. Bolting of racks together on the site is a tool‑less operation that can be carried out by one installer only. To asure proper functionality of the Air Separation frame in the ROF or RDF racks width 800 mm the HVMP/HVMF holders or extrusions type C or P (with blank panels) must be used.

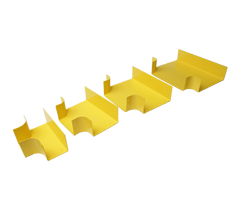

AIR FLOW Deflector - DP-AFD-ROF, DP-AFD-RSF The deflector is located in the bottom part of the rack and is used to leads the cold air from the raised floor space directly to the cold zone in the front part of the rack. Deflectors are designed ‑ for RSF/RDF and ROF racks. The ROF version designed for 600 or 800mm wide racks and can be installed into all ROF family racks of anz depth – from 600 to 1 200mm. Deflector helps control air-flow rates or shuts the air supply off if no equipment is fitted into the rack. The RDF/RSF version does not take up 19" space and can be installed in lieu of the front part of the rack's bottom cover.

CHIMNEY - DP-HPR

|

| AIR SEPARATION FRAME | ||||||

| Code | Cold zonedepth(mm) | H (in U) | Applicable for | W(mm) | Compatible extrusions | Package |

| DP‑ROF‑CW‑42/80/151 | 150 | 42 | RDF, RFS | 800 | L-type,P-type(RSF) | 1 pc of set 1 |

| DP‑RSF‑CW‑42/60/151 | 150 | 42 | RSF | 600 | T-type | 1 pc of set 1 |

| DP‑RSF‑CW‑42/80/151 | 150 | 42 | RSF | 800 | U-type | 1 pc of set 1 |

| DP‑RSF‑CWA‑42/601 | Variable | 42 | RSF, iSEVEN SERVER | 600 | A-type | 1 pc of set 1 |

| DP‑RSF‑CWA‑42/801 | Variable |

42 |

800 | A-type | 1 pc of set 1 | |

| DP-RXF-CW-48/60/5 | 50 | 42-48 | RSF, iSEVEN | 600 | L-type | 1 pc of set 2 |

| DP-RXF-CW-48/80/5 | 50 | 42-48 | RSF, RDF, iSEVEN | 800 | L-type | 1 pc of set 2 |

1 Height (42U) can be replaced by 45 or 48U

| AIRFLOW DEFLECTOR | |||||

| Code | Height | D (mm) | Aplicable | W(mm) | Package |

| DP‑AFD‑ROF‑80/80/15 |

2U | 42 | RDF | 800 | 1 set |

| DP‑AFD‑ROF‑80/100/15 |

2U | 42 | RDF | 800 | 1 set |

| DP‑AFD‑VF‑80 |

Variable Flow RateLouvre – 800 |

RDF | – | 1 set | |

| DP-AFD-RSF-60/15* | – | – | RSF | 600 | 1 set |

| DP-AFD-RSF-80/15* | – |

– |

RSF/RDF | 600 | 1 set |

Note: Cold zone depth 150 mm

* When used with A type extrusions, min. cold zone depth is 220 mm

| CHIMNEY | ||

| Code | Description | Package |

| DP‑HPR‑60/120‑B |

Designed for RSF‑XX‑60/120; color lightgray (RAL 7035) | 1 set |

| DP‑HPR‑60/120‑H |

Designed for RSF‑XX‑60/120; colorblack (RAL 9005) | 1 set |

| DP‑HPR‑80/120‑B |

Designed for RDF/RSF‑XX‑80/120;color light gray (RAL 7035) |

1 set |

| DP‑HPR‑80/120‑H | Designed for RDF/RSF‑XX‑80/120;color black (RAL 9005) | 1 set |

Datasheet Passive airflow management (PDF - 2.05MB)

Datasheet Passive airflow management (PDF - 2.05MB)

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS